Medical Components

We have been supplying medical components used within specialist equipment and devices, for over fifty years. Our manufacturing processes are subject to stringent quality control, placing us at the forefront of the supply industry.

Extensive Experience

MSP has been completing projects within the medical components industry for as long as we have been trading. Our position as the market-leading supplier of medical components is no accident. It is instead due to our consistent approach to high-quality manufacturing. We are committed to designing, innovating, and operating alongside our customers, using their facilities when necessary, to support their projects from the very beginning.

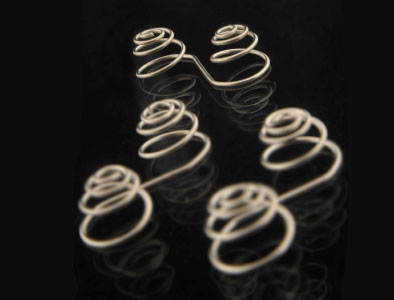

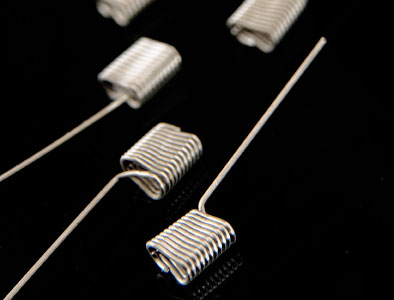

From thermal springs for cutting cartilage in surgical theatres to essential components for adrenaline pens that are used across the globe, we can produce all kinds of springs for medical components at MSP.

Accreditations And Accountability

MSP is committed to producing high-quality components that meet or exceed industry standards. We are able to guarantee this due to our aerospace accreditations, which assure our customers that we are operating with stringent quality controls and adhering to strict guidelines.

Only the best companies are accredited by the National Aerospace and Defense Contractors Accreditation Program (NADCAP), due to the rigorous assessments, requirements and standards.

ISO9001/AS9100

NADCAP certification for heat treatment

NADCAP certification for tensile testing

Cyber Essentials

From Concept To Completion

We have a global reputation for reliability. Our customers are secure in the knowledge that we can support them from initial concept through to serial production of high-volumes of medical components. The technical sales team at MSP remains a consistent point of contact in all of our long-standing working relationships, and someone is always available to address any questions or concerns.

In 2020, we manufactured day and night to support the NHS, and ensure that they had access to the large quantities of ventilation equipment that they required.

Production And Processes

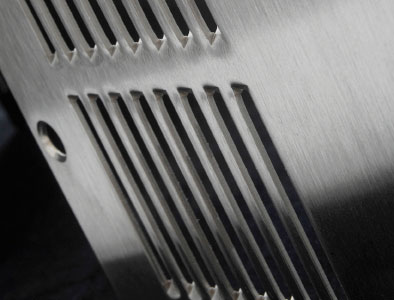

At MSP, we are proud to offer a quick turnaround for both samples and production. This is because our 40,000 sq. ft facility holds an extensive stock of medical-conforming raw materials – including wire, bar, sheet, and strip. This allows us to take on projects, no matter how big, small or complex, and provide accurate lead times that are unmatched across the industry.

While we provide springs for a diverse range of applications, across many different sectors, we are highly experienced in producing medical components. Cleaning and passivation processes are available as required, and so your project can be processed within a clean environment – from manufacture and assembly to testing and packaging.

Innovation

We are the go-to supply chain partner for many worldwide commercial and defence aerospace companies, offering value-added engineered solutions via ERP, VMI, KANBAN, safety buffer stocks and Kitting etc. Our dedicated team are passionate and proud of their work and always aim to exceed customer expectations, ensuring they go that extra mile.

Constant investment in people, plant and innovation is one of the things that sets MSP apart, and we are proud to actively engage with aerospace industry initiatives on the journey to Zero Defect manufacture.

Safety-critical and precision aerospace component manufacture is the mainstay of our business and is at the core of everything we do, giving us an unrivalled quality, OTIF (On Time In Full) capability, competitive pricing and enviable reputation. In addition to being AS9100 certified, we are NADCAP accredited (National Aerospace and Defence Contractors Accreditation Program), for Heat Treatment and Tensile Testing.

How Can MSP Help You?

Our highly experienced and highly qualified engineering team is passionate about their craft. Genuine enjoyment of what they do underpins their unrivaled knowledge and the exacting requirements that they must meet.

All of our springs are designed, manufactured, and tested with our customers in mind. This means that they are made specifically for your individual requirements – whether that be medical tools, hospital equipment, surgical beds, prosthetics, or something else entirely.

If you have any questions, would like to speak to one of our resident experts about how we can help, or are looking for the support of an experienced research and development team for an existing challenge, then please don’t hesitate to get in touch today.

You can call 01527 69121 or email us at email@springsandstampings.com.

We hope to hear from you soon! MSP is owned by Indutrade AB and has a UK sister company, Irvine Springs Ltd.